Part 2 of a two-part series. In this article, we examine the use of variable drum speed to alter heat transmission paths into the coffee beans.

By Paul Golding, Head Roaster at Paradox Coffee Roasters

Convective and conductive heating both have a part to play in the roasting of coffee. In all drum roasters, these heating paths are both in play to some degree; it is the design of the roasting system which determines just how the balance between the two is laid out. Using variable drum speed, it is possible to influence the time spent by the roasting beans in contact with the metal drum, and in contact with the hot air. This can be found to have an influence on the final flavour and attributes of the coffee.

Convective and conductive heating both have a part to play in the roasting of coffee. In all drum roasters, these heating paths are both in play to some degree; it is the design of the roasting system which determines just how the balance between the two is laid out. Using variable drum speed, it is possible to influence the time spent by the roasting beans in contact with the metal drum, and in contact with the hot air. This can be found to have an influence on the final flavour and attributes of the coffee.

Some fixed speed drum roasters with the gas burners directly under the steel drum can have roast times of up to thirty minutes in developing the coffee to the edge of second crack. Coffee from these machines can be delicious, with attributes often described as rich, spicy, caramel, chocolate, creamy, rounded. The slower roast times and flavours achieved point to plenty of conductive heating, with gentle convection making up the balance.

In contrast, a Brambati roaster keeps the burner remote from the coffee, injecting hot air to the drum space. This feature skews the Brambati system by default into the realm of powerful convective heating, with some conduction arising from the coffee contacting the air-heated metal of the drum. Typically, Brambati roasters of any size will complete a roast in 9-14 minutes depending on the program. Attributes of the coffee are generally described as crisp, clean, fruity, sweet, balanced, chocolate, caramel. Some factors here are in common with the slower roasters, but in general it is clear to see the differences resulting from the primarily convective heating.

It would not be fair to say that either style is better or worse than the other; they are simply different. From a production perspective it is certainly better to have a faster roast, but it is really a matter of what the roaster is trying to achieve to satisfy the customer.

At Paradox we offer blends which are styled to be quite differentiated; some acid driven and fruity, others caramelly, rich and softer in approach. Part of the differentiation is achieved by selection of the blend ingredients, however much of the variation comes from the method of roasting. There is a great advantage in being able to use the same origin in two different blends- this allows the roaster to buy more of that coffee from the producer, makes shipping more efficient, reducing inventory complexity and storage space. How do we use the same coffee, but make it taste so different for the separate blends? The answer lies in the roast profile, and the use of variable drum speed to adjust the heat transmission.

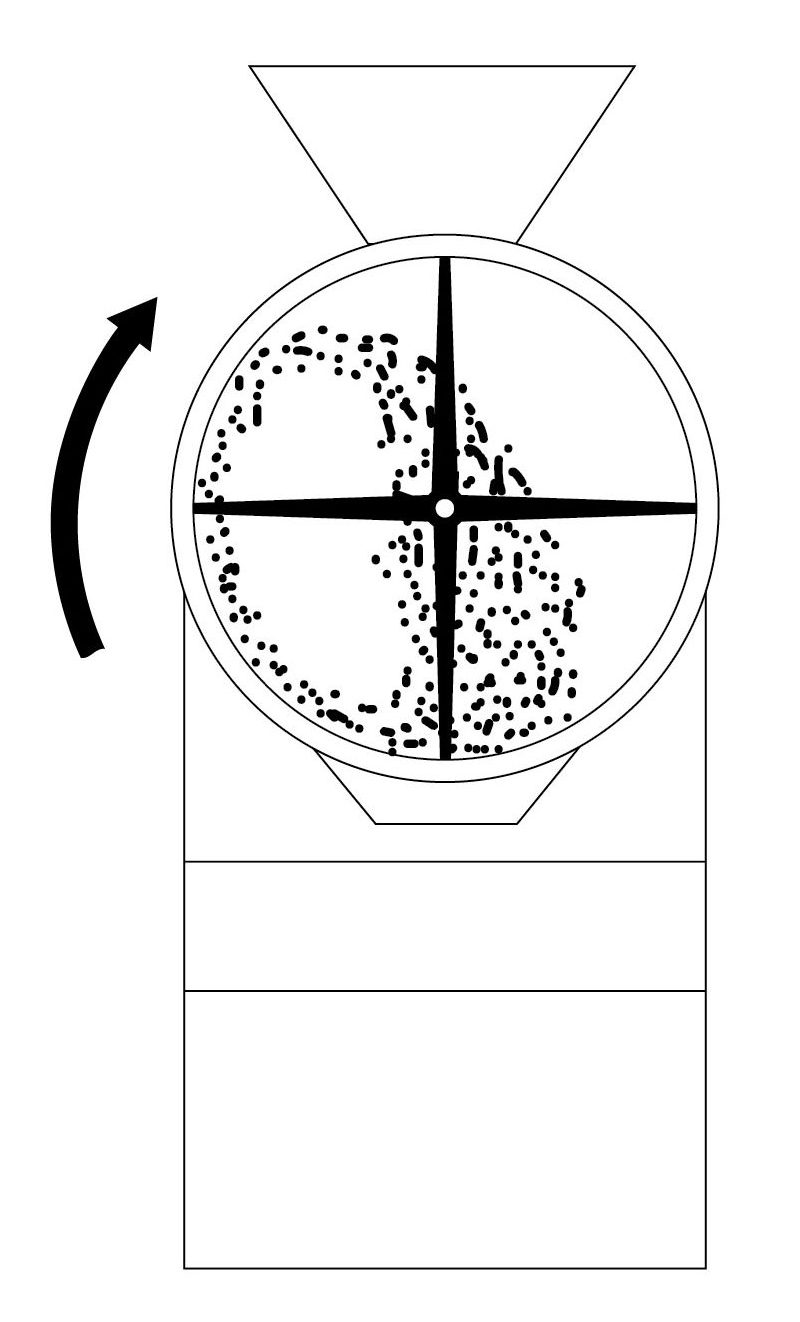

As stated above, the hot air injection system of a Brambati skews the heat transmission towards convective heating, so these roasters are known for coffee which is cleaner and more acidic. By running the roaster with high drum speed, the coffee is stirred rapidly by the internal fins, and tends to spend more time in the airspace than in contact with the drum. The risk of scorching the coffee during the fast roast is greatly reduced due to the minimal drum contact and the ability to reduce air temperature and pressure as the roasted beans develop and become more delicate.

This is a natural roast style for a Brambati, and not difficult to achieve. If we want the coffee to taste like it came from a more traditional roasting system, emphasising caramels, chocolate, and heavy bodied creaminess, we can simply reduce the burner temperatures and run a longer roast profile, we would be using extended convective heating to complete the roast. We might achieve some of our goals, however the nature of convective heating would surely result in some “baking” of the coffee or flattening of flavours, and possibly some dry astringency. Since caramelisation relies on higher temperatures, running the burner lower to extend the roast time may also reduce the perceived caramels.

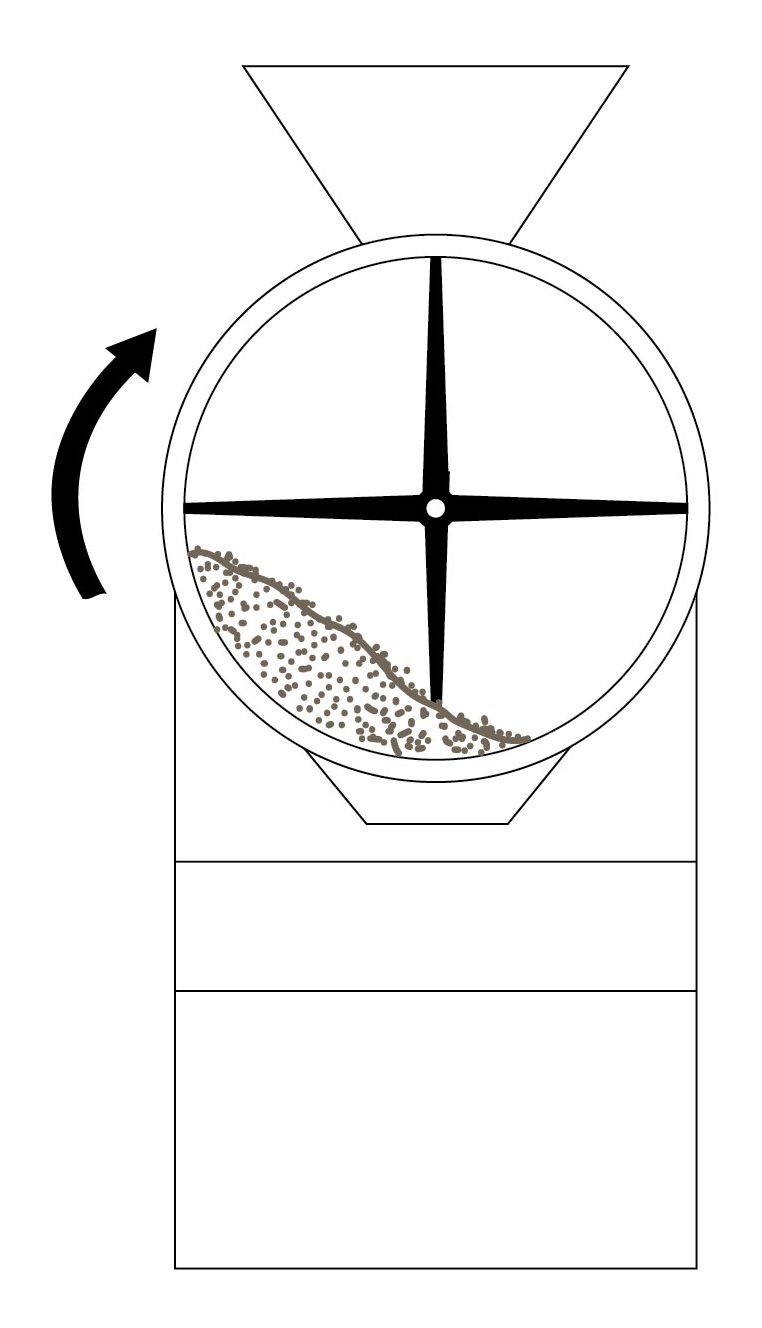

The answer lies not in altering burner settings, but in reducing the drum speed, and the air loop fan pressure. This action will increase the amount of time the coffee mass spends in contact with the drum metal, while leaving air temperature high enough for effective caramelisation. Convection is still present-this is a Brambati after all – but we have introduced significantly more conductive heating, which will help slow the roast enough to introduce conduction characters- heavier body, chocolate, caramel, spiciness.

The answer lies not in altering burner settings, but in reducing the drum speed, and the air loop fan pressure. This action will increase the amount of time the coffee mass spends in contact with the drum metal, while leaving air temperature high enough for effective caramelisation. Convection is still present-this is a Brambati after all – but we have introduced significantly more conductive heating, which will help slow the roast enough to introduce conduction characters- heavier body, chocolate, caramel, spiciness.

In this way we could roast the same Colombian coffee to 205˚C in 12 minutes, achieving a crisp, fruity cup, and 208 ˚C in 14 minutes, gaining heavier body, more perceived caramel and chocolate, while still retaining fresh flavours and some acidity. This can be done using virtually the same burner temperatures, varying only the drum speed and fan speed over the roast program. We can manage this without the risk of baking the coffee, as we have not removed heat energy to slow the roast, rather we have altered the ratio of the heat transmission to the coffee more in favour of conduction, taking advantage of the characters produced by conductive heating.